Within New Zealand, Unipharm has established high-standard, modern facilities constructed in accordance with GMP standards. All products are processed and manufactured in hundred-thousand-level cleanrooms that adhere to international HACCP standards. The facilities are equipped with international, fully automated production equipment and assembly lines.

We strive to develop higher quality nutritional products to help improve the life and health of our consumers. Every batch we produce is also sent to external, internationally accredited New Zealand laboratories for an additional assurance of quality before released to market. This cross-checking system provides extra assurance to our products.

—

Our Quality

In-house quality checks and multiple tests conducted by authoritative testing centers Eurofins and AsureQuality in New Zealand

Professional personnel conduct regular microbial sampling of equipment and production environments. Samples are sent to a third-party laboratory in New Zealand complying with ISO17025, ensuring product protection from microbial contamination.

Every batch of incoming raw materials undergoes thorough testing to ensure it does not impact the final product's quality. Suppliers of raw materials are also rigorously audited to ensure they have the capability to provide consistently high-quality materials.

Optimizing the dissolution of tablets and capsules within a defined timeframe.

This meticulous control

over the dissolution process enhances overall

bioavailability of the pharmaceutical formulation, ensuring effective therapeutic delivery.

Committing to maintaining contracted production standards, quality, and functionality throughout the production cycle, ensuring high quality.

Production facility testing

Strict monitoring of air and particles in the cleanroom ensures clean production lines, maintaining optimal conditions for product production and packaging.

retention

Finished products are stored in a temperature-controlled lab for long-term retention, with regular QA monitoring to ensure stability and functionality throughout their shelf life.

—

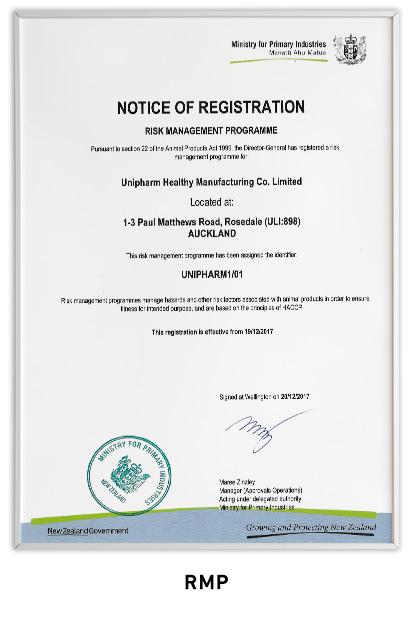

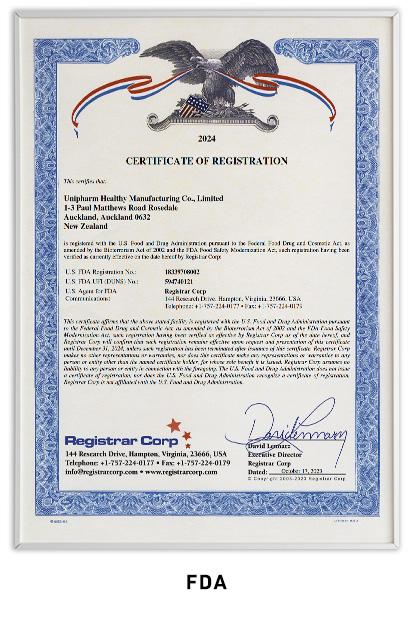

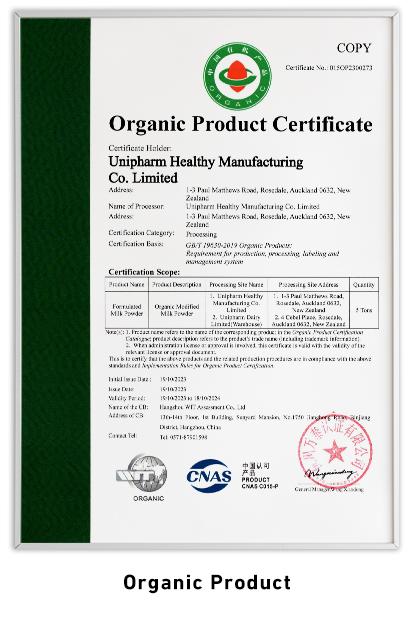

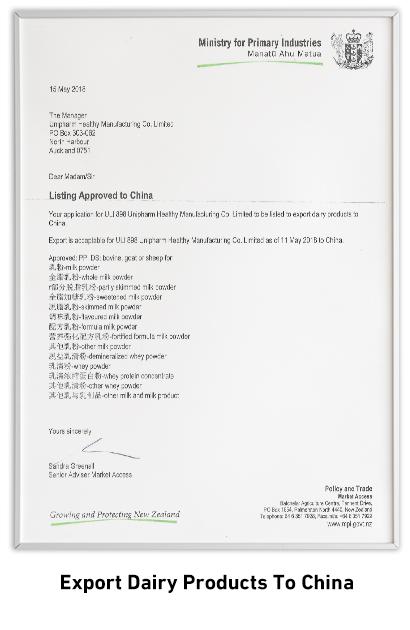

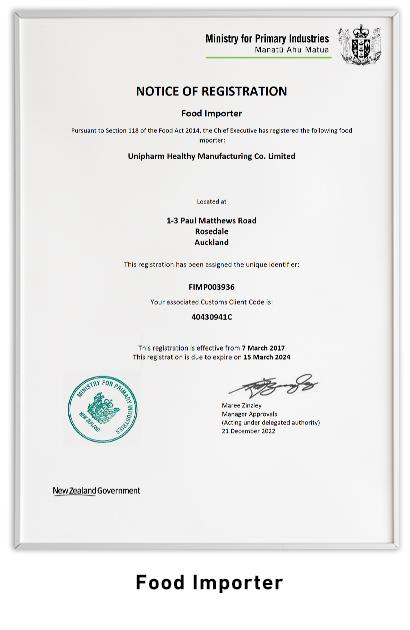

Certificates

28 global qualifications accredited by authoritative global institutions